Having a sustainable supply chain is no longer optional – it’s a necessity for businesses that want to remain competitive, resilient, and responsible. However, for SMEs, navigating the complexities of sustainability can feel overwhelming. That’s why having the right tools and frameworks is essential.

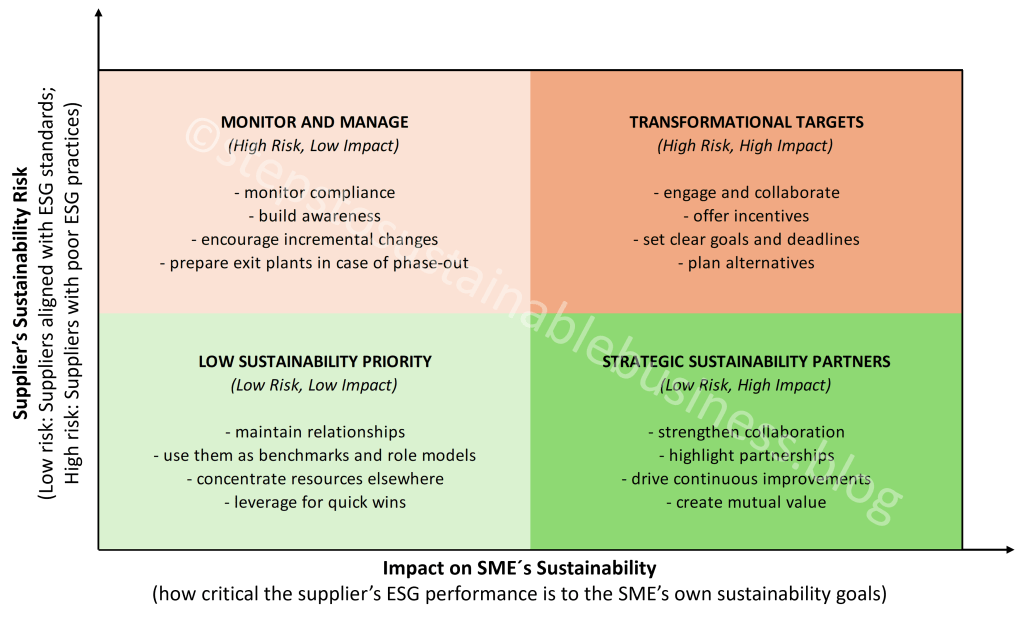

Welcome to our Sustainability Matrix for Supplier Management: a practical and easy-to-use tool we have prepared for SMEs to help them evaluate and improve supplier sustainability. This matrix doesn’t just identify problems; it provides actionable solutions for every type of supplier, from those lagging behind in ESG practices to those leading the charge. By using this framework, SMEs can make smarter decisions, prioritize resources, and turn sustainability into a competitive advantage. This approach draws inspiration from the Kraljic Matrix, a well-known supplier management tool, by classifying suppliers based on two key criteria: sustainability risk and impact on business goals.

In this article, we’ll show you step-by-step how to use the matrix to transform your supply chain into a sustainability powerhouse. Whether you’re just starting your journey or looking for ways to refine your approach, this tool is designed to help you succeed.

Why the Sustainability Matrix Matters

Our Matrix evaluates suppliers along two axes:

- Sustainability Risk: How poorly a supplier performs in terms of environmental, social, and governance (ESG) standards (e.g., high emissions, unethical labor practices, or lack of certifications).

- Impact on SME’s Sustainability: How critical the supplier’s ESG performance is to your own sustainability goals (e.g., if and to what extent their materials or practices directly affect your carbon footprint, and may impact your compliance, reputation, or client requirements).

This simple yet powerful tool enables SMEs to classify suppliers into four quadrants, each with a tailored strategy:

- Monitor and Manage (High Risk, Low Impact): For suppliers with poor ESG practices but limited influence on your sustainability goals.

- Transformational Targets (High Risk, High Impact): Suppliers with significant ESG risks that are crucial to your operations.

- Low Sustainability Priority (Low Risk, Low Impact): Suppliers with minimal sustainability risks and limited impact on your goals.

- Strategic Sustainability Partners (Low Risk, High Impact): High-performing suppliers essential to your sustainability efforts.

This structure empowers SMEs to act strategically; focusing on high-impact areas, building strong partnerships, and ensuring their supply chains align with their sustainability vision.

We will now guide you step by step through how to apply our Sustainability Matrix to evaluate and manage your suppliers effectively. By following these steps, you’ll be able to categorize your suppliers based on their sustainability performance and identify the most appropriate strategies for engaging with each one of them.

STEP 1: ASSESS AND CATEGORIZE YOUR SUPPLIERS

To start, you need to gather data about your suppliers’ ESG practices and their impact on your sustainability goals. Use some of the following tools to evaluate and classify them into the matrix:

- Supplier ESG Surveys: Create questionnaires to understand supplier practices related to emissions, waste management, labor, and governance. You can find some examples and templates for these questionnaires online, or create your own.

- Certifications and Audits: Check for compliance with standards like ISO 14001, FSC, or SA8000. These certifications offer reliable benchmarks.

- Scorecards and KPIs: Use a scoring system to rate suppliers based on sustainability performance, considering factors like emissions, water use, or packaging waste.

Once you’ve collected the data, map each supplier into one of the four quadrants of the matrix.

STEP 2: TAILORED ACTIONS FOR EACH QUADRANT

“Monitor and Manage” Quadrant (High Risk, Low Impact)

These suppliers pose sustainability risks but have limited influence on your business goals.

Example: This might be a low-cost supplier of packaging materials from a region with weak environmental regulations. They have poor waste management practices, but their products make up a small portion of your overall supply chain, so their environmental impact on your company is minimal.

What to Do:

1. Monitor Compliance

- Set Up Regular Audits: Conduct regular assessments of their ESG practices, such as labor conditions, emissions levels, and waste management protocols. Use standardized tools like ESG scorecards or supplier sustainability assessments to maintain objectivity.

- Request Transparency: Ask suppliers to share relevant data, such as energy use, water consumption, or ethical sourcing certifications. Regular reporting ensures they remain accountable.

- Leverage Technology: If available, use supply chain management software to track compliance and flag potential violations in real-time.

2. Encourage Incremental Changes

- Start Small: Suggest simple, low-cost measures, such as reducing single-use plastic in packaging or transitioning to energy-efficient equipment. These small steps can have a noticeable impact and set the stage for larger improvements.

- Provide Resources: Share case studies or examples of similar businesses that successfully adopted green practices, emphasizing how it benefited their efficiency and reputation.

- Offer Incentives: For example, promise increased volume or longer-term contracts if they demonstrate progress in sustainability initiatives (e.g. obtaining environmental certifications).

- Collaborate on Solutions: Co-develop solutions that align with both your ESG goals and their operational capabilities. This might include joint pilot projects to test sustainable materials or improve energy efficiency.

3. Prepare Exit Plans

- Conduct a Risk-Benefit Analysis: Regularly evaluate whether the supplier’s sustainability risks outweigh their strategic value to your business.

- Identify Alternatives: Begin researching and developing relationships with more sustainable suppliers to ensure a seamless transition when the time comes. Maintain an updated list of pre-vetted alternatives.

- Transition Gradually: If you replace the supplier, do so in phases to avoid supply chain disruptions. For example, you might start by diversifying, sourcing 20-30% of your needs from a new supplier before fully transitioning.

- Communicate Exit Reasons Transparently: When phasing out a supplier, provide clear feedback on the reasons, focusing on their ESG performance and the alignment with your sustainability goals.

“Transformational Targets” Quadrant (High Risk, High Impact)

These suppliers are critical to your operations but have poor ESG practices, making them top priorities for improvement.

Example: This could be a supplier of key components for your product (e.g. a manufacturer of electronic parts) which has been flagged for poor working conditions and a high carbon footprint. Despite their poor ESG practices, this supplier is crucial to your operations, and improving their sustainability standards is vital to maintaining your security of supply and achieving your own sustainability goals.

What to Do:

1. Engage and Collaborate

- Conduct Joint Assessments: Work with the supplier to identify the key areas where they need improvement, such as emissions reduction, ethical sourcing, or waste management. Use supplier assessment tools or ESG audits to establish a baseline.

- Provide Training: Offer workshops, online resources, or on-site training sessions on sustainability topics such as energy efficiency, waste reduction, or compliance with international labor standards.

- Form Green Partnerships: Collaborate on shared projects, such as co-developing greener materials or streamlining production processes to minimize waste and emissions.

- Regular Communication: Schedule regular meetings to discuss progress, challenges, and opportunities for mutual benefit. Assign dedicated points of contact to ensure clear and consistent dialogue.

2. Offer Incentives

- Financial Support: Help suppliers with obtaining subsidies, grants, or loans for specific sustainability investments, like installing solar panels or upgrading equipment to reduce emissions.

- Contractual Benefits: Promise longer-term agreements or increased order volumes contingent on meeting sustainability targets. For example, offer a three-year contract renewal if they achieve carbon neutrality by a specific date.

- Logistical Assistance: Help suppliers optimize their operations by sharing logistics solutions that reduce environmental impact, such as consolidating shipments or switching to eco-friendly transport modes.

3. Set Clear Goals and Deadlines

- Define Specific Targets: Outline measurable sustainability goals, such as reducing Scope 1 and 2 emissions by 20% within two years or achieving fair labor certification by the next audit cycle.

- Establish Timelines: Create phased deadlines for incremental improvements, like quarterly progress reviews and annual milestones, to track advancement toward the final target.

- Use Accountability Mechanisms: Sign formal agreements with suppliers to ensure commitment. Include clauses for monitoring progress and consequences for non-compliance, such as reduced orders or penalties.

- Leverage KPIs: Regularly track key performance indicators (KPIs), such as waste reduction rates, energy efficiency improvements, or worker safety metrics, and share results transparently with both parties.

4. Plan Alternatives

- Identify Backup Suppliers: Develop relationships with alternative suppliers that align with your ESG standards. This minimizes risks if a primary supplier fails to meet expectations.

- Mitigate Transition Risks: Start sourcing a percentage of critical components or materials from alternative suppliers while working with the current one. This ensures supply chain resilience without immediate disruptions.

- Evaluate Exit Criteria: Define clear thresholds for transitioning away from a supplier. For instance, if they fail to reduce emissions by a predetermined percentage within the agreed timeline, consider shifting to a more sustainable partner.

- Document the Process: Maintain clear records of engagement, improvement efforts, and the supplier’s performance to justify any transitions and inform future supplier relationships.

“Low Sustainability Priority” Quadrant (Low Risk, Low Impact)

These suppliers already meet basic ESG standards and have a minimal influence on your goals.

Example: This could be a stationery supplier that provides your office with basic items like pens, paper, and notepads. Their products are already made from recycled materials and sourced from certified sustainable manufacturers. However, because these supplies have no significant impact on your core business operations or ESG goals, they require minimal engagement beyond maintaining current standards.

What To Do:

1. Maintain Relationships

- Ensure Ongoing Compliance: Conduct occasional reviews to confirm suppliers continue meeting ESG standards, using tools like simplified self-assessment forms or periodic check-ins.

- Acknowledge Their Role: Recognize and appreciate their sustainability performance in annual supplier evaluations to foster goodwill and motivation.

2. Use Them as Role Models

- Share Best Practices: Document their ESG successes – like waste reduction techniques or eco-friendly material sourcing – and share these as examples during supplier workshops or newsletters.

- Organize Peer Learning: Host supplier roundtables or online meetings where low-priority suppliers can present their methods to inspire high-risk suppliers to adopt similar practices.

- Promote Visibility: Feature these suppliers on your web page, in your ESG reporting or case studies, showcasing them as key contributors to your sustainable supply chain.

3. Concentrate Resources Elsewhere

- Prioritize Higher-Impact Suppliers: Redirect audits, improvement programs, and resources toward suppliers in the High-Risk quadrants.

- Avoid Unnecessary Overhead: Limit excessive intervention unless opportunities for innovation or efficiency improvements arise that benefit both parties.

4. Leverage for Quick Wins

- Introduce Certifications: If feasible, encourage them to adopt additional low-cost certifications to boost their value in your supply chain.

- Collaborate for Small Improvements: Partner on easy, mutually beneficial projects, such as joint recycling programs or testing greener alternatives to existing materials.

“Strategic Sustainability Partners” Quadrant (Low Risk, High Impact)

These suppliers excel in ESG performance and are crucial to your sustainability goals.

Example: A solar energy provider supplying renewable power to your facilities. Their excellent ESG practices directly support your sustainability goals by significantly reducing your carbon footprint and enhancing energy efficiency.

What To Do:

1. Strengthen Collaboration

- Co-Innovation Projects: Work closely with these suppliers to co-develop new, sustainable products or processes. For example, collaborate on designing biodegradable packaging or creating energy-efficient supply chain solutions.

- Joint Sustainability Programs: Launch shared initiatives, such as reducing water usage in production, or implementing renewable energy solutions across shared facilities or processes.

- Data Sharing: Exchange sustainability performance data (e.g., energy usage, waste metrics) to identify opportunities for joint improvement. Use shared dashboards or collaborative tools to track and optimize efforts.

- Exclusive Partnerships: Where desirable, establish exclusivity agreements for specific sustainable innovations to ensure both parties benefit financially and reputationally from their development.

2. Highlight Partnerships

- ESG Reporting: Feature these suppliers prominently in your sustainability reports, showcasing the impact of your collaboration on key metrics, such as emissions reductions or waste minimization.

- Case Studies and Testimonials: Create and publish case studies detailing your joint achievements, such as transitioning to zero-emission manufacturing. Use these stories in marketing campaigns, industry events, and awards submissions.

- Recognition Programs: Publicly recognize these suppliers during events, in newsletters, or via press releases to promote their contribution to your shared goals and to encourage other suppliers to follow their lead.

3. Drive Continuous Improvement

- Ambitious Goal-Setting: Work together to set bold, long-term objectives like achieving net-zero emissions, transitioning to circular economy principles, or becoming carbon positive. Establish measurable milestones along the way.

- Invest in Research: Pool resources for joint R&D projects, such as developing cutting-edge green technologies or creating supply chain transparency tools.

- Benchmarking Excellence: Encourage these suppliers to push boundaries by participating in industry benchmarks or sustainability certifications. Offer support during these efforts to ensure success.

- Feedback Loops: Schedule regular performance reviews to identify new areas of opportunity, celebrating achievements and refining goals as needed to maintain momentum.

4. Create Mutual Value

- Revenue Opportunities: Explore new markets or product lines that capitalize on the supplier’s sustainability expertise (for instance, you can develop eco-labels or green product certifications together).

- Shared Branding: Leverage co-branding opportunities to emphasize your shared commitment to sustainability, enhancing both parties’ reputation.

- Scalability: Expand the supplier’s innovations across your supply chain or customer base, amplifying their impact and creating a multiplier effect for sustainability.

STEP 3: MONITOR PROGRESS AND ADAPT

Sustainability isn’t a one-and-done effort; it’s an ongoing process that requires continuous monitoring and adaptation. Use these steps to stay on track:

- Leverage Technology: Tools like IoT sensors or sustainability tracking platforms can help measure supplier performance in real-time.

- Set KPIs: Track metrics like emissions, waste, or water consumption to measure progress and adjust strategies as needed.

- Communicate Results: Share your successes (and challenges) with stakeholders through sustainability reports or newsletters. Transparency builds trust and attracts eco-conscious customers.

Conclusion: Turn Sustainability into Your Competitive Edge

The Sustainability Matrix isn’t just a tool – it’s your roadmap to building a greener, more resilient supply chain. By assessing suppliers, tailoring your strategies, and prioritizing high-impact areas, you can turn sustainability from a challenge into a competitive advantage.

Remember, every step you take (whether it’s mentoring a struggling supplier, collaborating with a strategic partner, or phasing out high-risk suppliers) brings you closer to a supply chain that reflects your values and goals.

It’s time to take the lead, use the Sustainability Matrix, and show the world that SMEs can drive meaningful change. Start small, stay consistent, and watch as your efforts inspire both your team and your stakeholders. The future of your business (and the planet) depends on it.

Leave a reply to Sustainability Glossary Series: Part 5 (Sustainable E-Commerce Concepts) – Steps to Sustainable Business Cancel reply