In my previous article on 5 Common Sustainability Mistakes SMEs Make, we discussed how failing to evaluate suppliers’ sustainability practices is a significant pitfall. While there are more sophisticated, digital solutions available to track and assess supplier performance, these tools may not always be suitable for SMEs due to cost and technical constraints. This is where supplier sustainability scorecards – a simple, cost-effective, and customizable tool – come in handy, offering an accessible solution for SMEs to evaluate their suppliers’ sustainability practices effectively. They provide SMEs with a structured way to ensure their sourcing decisions align with their environmental, social, and governance (ESG) goals.

This article explores how SMEs can start using scorecards to build more sustainable, transparent supply chains and foster stronger supplier relationships.

What Are Supplier Scorecards?

A supplier scorecard is a tool used to assess and track a supplier’s performance based on a set of criteria, which may include quality, delivery, cost, and sustainability. In the context of sustainability, a supplier scorecard helps businesses evaluate how well their suppliers align with their ESG goals. It provides a structured approach to monitor performance over time, ensuring that suppliers meet the required standards, and enables businesses to make informed decisions about their supply chain.

A supplier scorecard is a tool used to assess and track a supplier’s performance based on a set of criteria, which may include quality, delivery, cost, and sustainability. In the context of sustainability, a supplier scorecard helps businesses evaluate how well their suppliers align with their ESG goals. It provides a structured approach to monitor performance over time, ensuring that suppliers meet the required standards, and enables businesses to make informed decisions about their supply chain.

The Benefits of Using Supplier Sustainability Scorecards

- Improved Supplier Performance and Accountability: Supplier scorecards create a simple but objective framework that allows SMEs to regularly evaluate their suppliers across key sustainability criteria. By tracking performance and identifying areas for improvement, businesses can foster a culture of accountability and gradually push for better sustainability practices. Over time, this results in improved environmental impact, social responsibility, and operational efficiency.

Example: A small electronics manufacturer uses a scorecard to assess its component suppliers on emissions reductions and waste management practices. Based on scorecard feedback, one supplier improves its packaging processes, reducing waste and energy consumption, resulting in cost savings for both parties.

Example: A small electronics manufacturer uses a scorecard to assess its component suppliers on emissions reductions and waste management practices. Based on scorecard feedback, one supplier improves its packaging processes, reducing waste and energy consumption, resulting in cost savings for both parties.

- Informed Decision Making: By utilizing a supplier scorecard, SMEs gain the data they need to make informed, strategic decisions about their supplier relationships. This tool helps businesses identify which suppliers align with their sustainability objectives and which might require further engagement or even replacement (see my Supplier Sustainability Matrix for supplier management) .

Example: A boutique retailer assesses its fabric suppliers on sustainability practices such as water usage and carbon emissions. One supplier consistently scores low on water conservation, prompting the retailer to seek alternatives that better align with its green goals, thereby reducing its own risk.

Example: A boutique retailer assesses its fabric suppliers on sustainability practices such as water usage and carbon emissions. One supplier consistently scores low on water conservation, prompting the retailer to seek alternatives that better align with its green goals, thereby reducing its own risk.

- Enhanced Collaboration and Supplier Innovation: Supplier scorecards are not only about monitoring supplier performance but also about fostering collaboration. Suppliers that are assessed regularly can receive constructive feedback, which can spark innovation. Working together to solve sustainability challenges creates opportunities for both parties to improve their processes.

Example: A sustainable fashion company uses scorecards to evaluate their dye suppliers. They provide feedback to a supplier whose waste disposal practices are lacking. The supplier, motivated to improve in order to maintain the client, then innovates by developing a new waterless dyeing technique, reducing environmental impact and improving their scorecard rating.

Example: A sustainable fashion company uses scorecards to evaluate their dye suppliers. They provide feedback to a supplier whose waste disposal practices are lacking. The supplier, motivated to improve in order to maintain the client, then innovates by developing a new waterless dyeing technique, reducing environmental impact and improving their scorecard rating.

- Improved Risk Management: Managing supplier risk related to ESG is becoming more and more important for businesses today. Supplier scorecards help SMEs stay ahead of potential risks by identifying non-compliant suppliers, especially those with poor environmental or labor practices. Early identification allows businesses to take corrective actions before issues escalate.

Example: A food supplier uses a scorecard to evaluate sourcing practices from its agriculture suppliers. One supplier scores poorly on labor practices, prompting the company to request further details to clarify the situation or find a new source that complies with its ethical standards.

Example: A food supplier uses a scorecard to evaluate sourcing practices from its agriculture suppliers. One supplier scores poorly on labor practices, prompting the company to request further details to clarify the situation or find a new source that complies with its ethical standards.

- Supporting Regulatory Compliance: As sustainability regulations tighten, particularly with frameworks like the Corporate Sustainability Reporting Directive (CSRD) in the EU, supplier scorecards are a proactive way for SMEs to ensure compliance. By tracking key ESG metrics, businesses can ensure their suppliers meet the required standards and can provide the necessary documentation for regulatory reporting.

Example: A European SME in manufacturing uses its scorecard to track supplier compliance with EU waste management regulations. This practice ensures the company stays compliant with the EU’s circular economy targets and simplifies its own regulatory reporting.

Example: A European SME in manufacturing uses its scorecard to track supplier compliance with EU waste management regulations. This practice ensures the company stays compliant with the EU’s circular economy targets and simplifies its own regulatory reporting.

Creating a Supplier Sustainability Scorecard – A Step-by-Step Guide

Creating a supplier sustainability scorecard is a structured process. Here’s an example breakdown of how to do it:

- GATHERING DATA: To populate the scorecard, gather data from suppliers using a combination of methods:

- Supplier Self-Assessments: Distribute questionnaires to suppliers, asking about their sustainability practices in areas like energy use, waste management, and labor standards. These assessments should be tailored to the specific sustainability criteria of your scorecard.

- Certifications and Audits: Whenever available, request independent supporting evidence such as ISO certifications, environmental audits, or third-party sustainability reports.

- Direct Conversations: If certifications are unavailable, engage with suppliers directly to understand their practices. You may ask for documentation like internal sustainability reports, policies, energy bills, or waste management practices.

When preparing questions for your suppliers, focus on several core areas that align with your sustainability goals:

- Environmental Impact (carbon emissions, energy usage, waste management, use of resources, water consumption)

- Social Responsibility (labor practices, diversity and inclusion, fair wages, and health and safety)

- Governance (compliance with ethical standards, transparency, and regulatory adherence)

If you’re just starting to integrate sustainability into your supply chain, begin with simple, clear questions like those found in the example template later in this article:

- Do suppliers have waste reduction plans?

- Are products ethically sourced?

- Do they track energy consumption?

These initial questions help establish a basic understanding of your suppliers’ sustainability efforts. As you gain more experience and confidence, you can gradually introduce more complex, measurable KPIs into your assessments. For example, metrics like Carbon Emissions (kg/unit), Renewable Energy Use (%), Waste Recycled (%), and Water Use Reduction (%) provide a more quantitative approach to supplier performance, enabling you to make more informed, strategic decisions.

Here are some simple example questions that you can ask yourself in relation to your suppliers when trying to assess their sustainability practices across the key areas:

Environmental Impact:

- Do they track their carbon emissions regularly?

- Do they have a waste reduction plan in place?

- Is their company committed to reducing energy consumption?

- Do they use recycled materials in their products?

- Do they have an official water conservation policy?

Social Responsibility:

- Do they comply with local labor laws regarding wages and working hours?

- Do they provide health and safety training to their employees?

- Do they have a diversity and inclusion policy?

- Do they engage with the local community or participate in charitable initiatives?

- Are their products ethically sourced?

Governance:

- Do they have a transparent reporting process for sustainability goals?

- Do they comply with anti-corruption laws in their business operations?

- Do they conduct regular audits to assess their sustainability performance?

- Do they disclose their environmental and social performance publicly?

- Do they have a formal code of ethics for their business operations?

Operational Efficiency:

- Do they optimize energy use in their production processes?

- Do they monitor and reduce waste in their manufacturing processes?

- Do they minimize transportation-related emissions by consolidating shipments?

- Do they use efficient machinery and equipment to reduce resource consumption?

- Do they have a plan to improve the sustainability of their supply chain?

Note: When customizing questions for your supplier scorecard, make sure they align with your specific sustainability goals. Tailor the questions based on factors like the supplier’s size, industry, and your own ESG priorities.

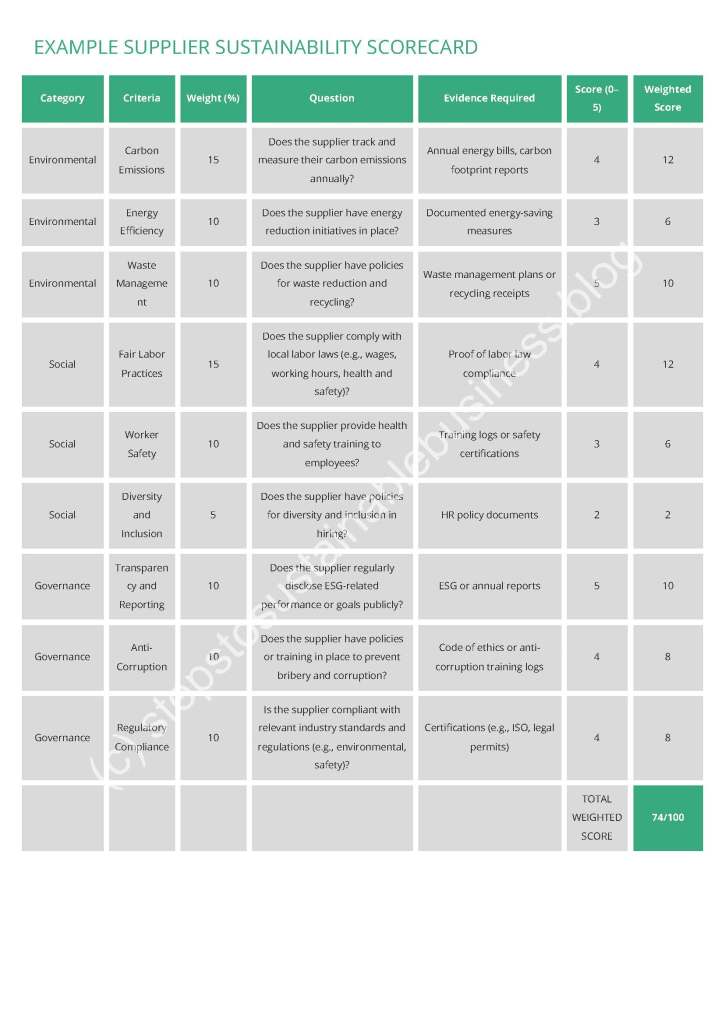

- SCORING SYSTEM AND ASSIGNING SCORES: According to their relevance, assign weight to each one of the criteria and decide on a score for each category, based on supplier performance, for example on a 0-5 point scale:

- 0 points: No compliance or evidence.

- 1 point: Minimal compliance; no active initiatives.

- 3 points: Partial compliance; some evidence but needs improvement.

- 5 points: Full compliance; strong evidence of sustainability leadership.

- FINAL SCORE CALCULATION: Once you’ve assessed each category and calculated the weighted scores (by multiplying each score by its weight percentage), calculate an overall score by adding up the individual category scores.

Example Supplier Scorecard

Below is an example of a supplier scorecard that SMEs can use to assess their suppliers based on sustainability criteria:

How to Use a Supplier Scorecard Effectively

- Create Clear KPIs: Choose criteria that align with your sustainability goals.

- Evaluate Regularly: Perform assessments at regular intervals to monitor supplier performance.

- Engage Suppliers: Share the scorecard results with suppliers, set goals, and encourage improvements.

- Develop Action Plans: For underperforming suppliers, collaborate to create corrective action plans with clear timelines.

- Track Progress: Regularly update scorecards and track improvements to maintain momentum.

- Start Small and Build Gradually: If you’re new to supplier scorecards, begin with a straightforward approach. Select a few criteria and apply them to a manageable number of suppliers.

As you gain confidence in the process and identify what works best, expand the scope by adding more criteria, starting to measure specific KPIs and including additional suppliers. This approach ensures that the system remains practical and avoids overwhelming your team.

Conclusion

Supplier scorecards are a vital tool for SMEs looking to integrate sustainability into their supply chain practices. By evaluating suppliers across key ESG criteria, SMEs can make informed decisions, improve supplier relationships, and ensure long-term business resilience. Implementing a scorecard can also provide a competitive edge, helping SMEs stay ahead of regulations and market trends, all while contributing to a more sustainable future.

Start using a supplier scorecard today, and build a supply chain that aligns with your business’s sustainability goals.

What is your experience with supply chain sustainability and its challenges? Do you have any ideas or tips you would like to share or questions you would like to ask? Write your comments and subscribe to my blog for more contents like this.

Leave a reply to Learn how to use scorecards to make your supply chain more sustainable! – Steps to Sustainable Business Cancel reply