The global economy is shifting away from wasteful, resource-intensive practices towards sustainability, and the circular economy is a part of this transformation. For small and medium-sized enterprises (SMEs), circularity offers not just environmental benefits but also economic opportunities. By rethinking how resources are used, shared, and reused, SMEs could become drivers of innovation and efficiency while meeting growing customer demand for sustainable practices.

This article explores four practical strategies – eco-design (design for circularity), industrial symbiosis, reverse logistics, and the shift to “product-as-a-service” business models – that SMEs can use to transition from linear operations to circular systems. Additionally, we will provide a simple and actionable guide which can help your business ask the right questions and start exploring opportunities for adopting circular economy principles in its daily operations.

First, let´s have a quick look at what circular economy means (video by the Ellen MacArthur Foundation):

Challenges in Adopting Circularity for SMEs

While the benefits of circularity are clear, SMEs may encounter several challenges when adopting circular practices:

- Financial Constraints:

Circular economy initiatives often require upfront investment in new technologies, processes, or infrastructure. SMEs may face difficulty securing the necessary capital or financial support to initiate these changes. - Knowledge and Expertise:

Many SMEs may lack the technical knowledge or expertise needed to implement circular practices. Designing products for circularity, optimizing supply chains for resource recovery, or understanding complex waste management systems can be challenging. - Regulatory Complexity:

SMEs may struggle to keep up with the evolving compliance requirements related to waste management, energy efficiency, or recycling. Understanding the regulations can be a hurdle, especially for smaller businesses. - Operational Disruptions:

Transitioning to a circular economy may require significant changes in business models. These may disrupt existing workflows, which can be challenging for SMEs that are accustomed to traditional business practices. - Supply Chain Coordination:

Circularity often involves collaboration with suppliers, partners, and other businesses. SMEs may find it difficult to coordinate and establish trust, especially when dealing with new technologies or systems.

Why SMEs Should Try to Embrace Circularity

While all these challenges are valid, the benefits of adopting circular practices can help SMEs overcome these obstacles, positioning them for sustained growth and competitive advantage in an increasingly eco-conscious marketplace. Here are some of the key positive impacts:

- Economic Benefits:

Despite financial constraints, circularity presents opportunities for cost savings through resource efficiency, new revenue streams from waste recovery, and competitive differentiation. Although the initial investment may be high, over time, the savings from reduced resource use and the ability to generate revenue from waste has the potential to outweigh the costs. Additionally, circularity can enhance an SME’s brand reputation, making them more attractive to customers, investors, and suppliers.

DID YOU KNOW that discarded mobile phones in Europe alone represent a material loss of up to USD 500 million annually? With valuable resources such as gold and rare earth elements embedded in these devices, SMEs can realize the economic potential of recycling and repurposing electronic waste. (Source: Ellen MacArthur Foundation, Towards the circular economy Vol. 1, 2013)

DID YOU KNOW that discarded mobile phones in Europe alone represent a material loss of up to USD 500 million annually? With valuable resources such as gold and rare earth elements embedded in these devices, SMEs can realize the economic potential of recycling and repurposing electronic waste. (Source: Ellen MacArthur Foundation, Towards the circular economy Vol. 1, 2013)

- Environmental Impact:

Although navigating regulatory complexity can be challenging, adopting circular practices helps SMEs stay ahead of stricter environmental regulations. Circularity supports reduced waste, lower carbon footprints, and improved resource efficiency. By integrating these practices early, SMEs can avoid future compliance penalties and position themselves as leaders in environmental stewardship, appealing to eco-conscious consumers. - Customer Demand:

While operational disruptions can occur when adopting new business models, the growing demand for eco-friendly products makes it worthwhile. Eco-conscious consumers increasingly favor businesses that prioritize sustainability. By adopting circular practices, SMEs can improve customer loyalty, enhance brand differentiation, and attract customers who value sustainable and responsible business practices. - Long-Term Resilience:

Transitioning to circularity, though complex and sometimes difficult due to supply chain coordination, ultimately helps SMEs future-proof their operations. Circular practices reduce reliance on finite resources, making businesses more resilient to supply chain disruptions and resource scarcity.

Transitioning to circularity may seem daunting, but by adopting targeted strategies, SMEs can achieve impactful results without overhauling their entire operations. Below, we explore some of the key approaches tailored for SMEs:

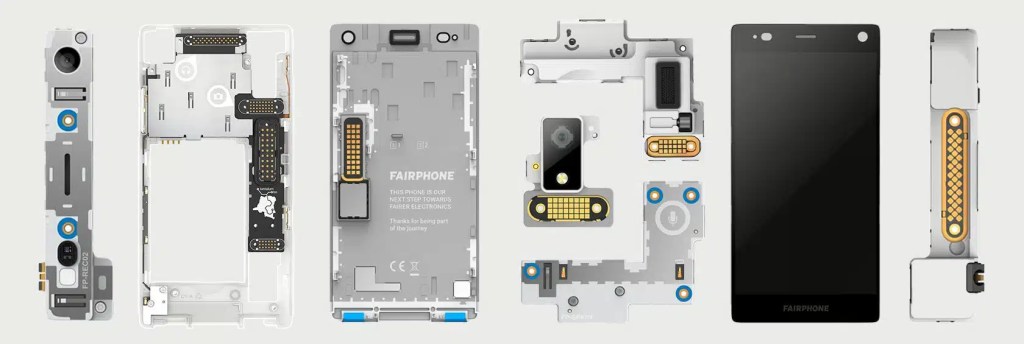

1. ECO-DESIGN (DESIGN FOR CIRCULARITY): CREATING PRODUCTS FOR SUSTAINABLE FUTURE

What It Is: Eco-design, or design for circularity, involves creating products with their entire lifecycle in mind. This means designing products that are durable, easy to repair, upgrade, or disassemble for reuse, recycling, or remanufacturing. The goal is to reduce the environmental impact from the very beginning—during the design phase.

What It Is: Eco-design, or design for circularity, involves creating products with their entire lifecycle in mind. This means designing products that are durable, easy to repair, upgrade, or disassemble for reuse, recycling, or remanufacturing. The goal is to reduce the environmental impact from the very beginning—during the design phase.

How SMEs Can Leverage It:

- Use Sustainable Materials: Select materials that are renewable, recyclable, or biodegradable.

- Modular Design: Create products with replaceable parts, enabling easier repair and upgrading.

- Simplify Disassembly: Design products so they can be easily taken apart to separate materials for recycling or reuse.

Benefits:

- Reduces waste and resource consumption by extending the product’s lifecycle.

- Increases customer satisfaction through longer-lasting, high-quality products.

- Aligns with increasing consumer demand for eco-friendly products.

- Competitive Advantage: Adopting eco-design can differentiate an SME from competitors by offering innovative, sustainable products that resonate with eco-conscious consumers.

Example: Fairphone, a Dutch modular smartphone manufacturer, is a great example of how eco-design can work on a small scale. They focus on repairability, allowing users to fix their phones easily replacing the different components, which minimizes waste and enhances product longevity.

Example: Fairphone, a Dutch modular smartphone manufacturer, is a great example of how eco-design can work on a small scale. They focus on repairability, allowing users to fix their phones easily replacing the different components, which minimizes waste and enhances product longevity.

Source: http://www.fairphone.com

Takeaway for SMEs:

Eco-design is usually highly feasible for SMEs and can offer both environmental and economic benefits. By incorporating sustainable practices into product design, SMEs can increase their competitiveness while reducing waste and resource consumption.

2. INDUSTRIAL SYMBIOSIS: COLLABORATING FOR RESOURCE EFFICIENCY

What It Is: Industrial symbiosis (IS) applies the principles of natural ecosystems to industrial systems, where waste from one process becomes the input for another. Businesses in a network collaborate to share materials, energy, and waste, optimizing resource use across the system.

What It Is: Industrial symbiosis (IS) applies the principles of natural ecosystems to industrial systems, where waste from one process becomes the input for another. Businesses in a network collaborate to share materials, energy, and waste, optimizing resource use across the system.

How SMEs Can Leverage It:

- Collaborate Locally: SMEs in industrial clusters or parks can share resources like heat, water, or waste treatment facilities.

- Identify By-Product Uses: Find partners who can use your waste as raw materials or energy inputs.

- Pursue Shared Infrastructure: Co-invest in renewable energy systems, water recycling plants, or centralized waste management.

Example: The Kalundborg Symbiosis in Denmark is a groundbreaking partnership of sixteen companies that has transformed waste streams into resources since 1972, creating the world’s first industrial symbiosis with a circular approach to production. This collaboration delivers significant environmental and economic benefits, saving 4 million m³ of groundwater annually by using surface water, recycling 62,000 tonnes of residual materials, and reducing 586,000 tons of CO₂ emissions. Since 2015, the symbiosis has achieved an 80% reduction in CO₂ emissions, with the local energy supply now carbon-neutral. By minimizing waste, cutting costs, and fostering local growth, Kalundborg Symbiosis exemplifies the potential of industrial symbiosis to drive the green transition and sustainable innovation.

Example: The Kalundborg Symbiosis in Denmark is a groundbreaking partnership of sixteen companies that has transformed waste streams into resources since 1972, creating the world’s first industrial symbiosis with a circular approach to production. This collaboration delivers significant environmental and economic benefits, saving 4 million m³ of groundwater annually by using surface water, recycling 62,000 tonnes of residual materials, and reducing 586,000 tons of CO₂ emissions. Since 2015, the symbiosis has achieved an 80% reduction in CO₂ emissions, with the local energy supply now carbon-neutral. By minimizing waste, cutting costs, and fostering local growth, Kalundborg Symbiosis exemplifies the potential of industrial symbiosis to drive the green transition and sustainable innovation.

Takeaway for SMEs:

Even small-scale collaborations—such as sharing logistics or recycling systems—can deliver savings and sustainability benefits. Collaborative efforts can help SMEs share costs, access new technologies, and reduce their environmental footprint.

3. REVERSE LOGISTICS: TURNING WASTE INTO OPPORTUNITY

What It Is: Reverse logistics focuses on moving goods from the consumer back to the producer for repair, refurbishment, recycling, or proper disposal. It closes the loop by extending the lifecycle of products and recovering valuable materials.

What It Is: Reverse logistics focuses on moving goods from the consumer back to the producer for repair, refurbishment, recycling, or proper disposal. It closes the loop by extending the lifecycle of products and recovering valuable materials.

How SMEs Can Implement It:

- Establish Take-Back Programs: Encourage customers to return used products, offering incentives or discounts.

- Partner for Processing: Collaborate with recycling or logistics companies to manage product returns efficiently.

- Create New Revenue Streams: Refurbish returned goods or repurpose recovered materials into new products.

Examples:

Examples:

- Liofit (Germany) repairs defective e-bike batteries, significantly extending their lifespan and reducing electronic waste. By addressing a common industry challenge, the company has carved out a niche market while supporting circularity.

- Lush cosmetics has implemented a container take-back scheme where customers can return used cosmetic pots in exchange for discounts or free products. These containers are then cleaned, shredded, and recycled into new packaging, closing the loop within their supply chain. This initiative aligns with circular principles by reducing plastic waste and promoting reuse.

Takeaway for SMEs:

Reverse logistics is particularly valuable for SMEs in electronics, fashion, or manufacturing, where high-value materials can be reclaimed and reused. It’s also a way to foster customer loyalty, as consumers increasingly value businesses that take responsibility for their products post-consumption.

4. “PRODUCTS-AS-A-SERVICE” BUSINESS MODEL: OFFERING ACCESS OVER OWNERSHIP

What It Is: Shifting from selling products to renting or leasing them focuses on providing access to functionality rather than ownership. This approach incentivizes durable design and aligns with the principles of the circular economy.

What It Is: Shifting from selling products to renting or leasing them focuses on providing access to functionality rather than ownership. This approach incentivizes durable design and aligns with the principles of the circular economy.

How SMEs Can Apply It:

- Pilot Rental Services: Start with a small-scale rental program for durable goods, like tools, equipment, or electronics.

- Integrate Maintenance Services: Offer repair and maintenance as part of the package to extend product lifespans.

- Promote Flexibility: Highlight cost savings and convenience for customers, especially in sectors like fashion, furniture, and appliances.

Examples:

Examples:

- Light as a Service at Schiphol Airport, Netherlands: Schiphol Airport, aiming to be the world’s most sustainable airport, collaborates with Signify (formerly Philips) to implement “Light as a Service.” Instead of purchasing lighting outright, Schiphol pays an annual fee for performance, and Signify retains ownership. This circular model reduces energy use by 50%, ensures lighting performance, and guarantees the recycling and reuse of the infrastructure at the end of the contract.

- Grover – Electronics Subscription (Germany): Grover offers electronic devices like smartphones, laptops, and cameras on a monthly subscription basis. Customers pay for access instead of ownership, and Grover remains responsible for repairs, upgrades, and recycling. This reduces e-waste and increases the utilization of devices throughout their lifecycle.

Takeaway for SMEs:

By shifting to “rent” models, SMEs can unlock recurring revenue streams while strengthening customer loyalty and reducing environmental impact. This model is highly adaptable, with industries ranging from fashion to technology and beyond.

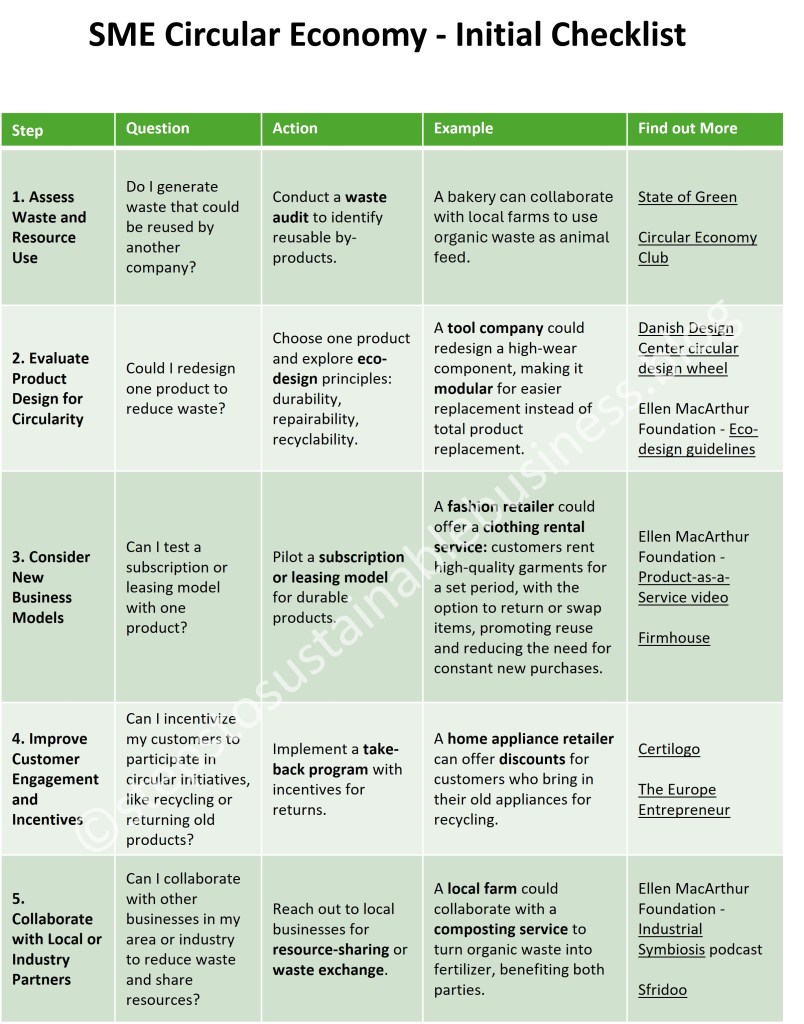

Checklist for SMEs: Taking the First Step Towards Circularity

Adopting circular economy practices can seem daunting for SMEs. However, the transition to a circular model doesn’t have to happen overnight. By starting with small, manageable steps, SMEs can gradually integrate circular practices that not only benefit the environment but also unlock significant economic opportunities. The following checklist is designed to help businesses take their first steps toward circularity. It provides actionable questions and practical actions that will allow you to evaluate your current operations and identify easy wins:

Conclusion

For SMEs, the circular economy is not just an environmental imperative—it’s a competitive advantage. By adopting strategies like eco-design, industrial ecology, reverse logistics, and the “product as a service” business model, SMEs can reduce costs, innovate sustainably, and attract eco-conscious customers. The journey may require upfront effort, but the long-term rewards—economic, environmental, and social—can be transformative.

Circularity is a step-by-step process, and in spite of its challenges, SMEs have the flexibility to start small and scale up. Whether you’re designing sustainable products, collaborating with neighboring businesses, reclaiming materials, or offering services instead of products, every action contributes to a sustainable future.

Ready to take your first step toward circularity? Explore these strategies, experiment with one or more, and share your experiences with the growing community of circular businesses! Make sure to subscribe to my blog for more contents like this.

Leave a comment